Application of Gafford inverter in rotary cutter

Overview

With the increasing lack of forest resources, the comprehensive utilization of wood resources has become an important issue for woodworking equipment manufacturing and wood processing industry. At present, in the process of veneer production, the multi-layer panel manufacturers adopt the traditional center-clamped log veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer vene. However, due to the existence of the core, when the diameter of the veneer is about 200mm, it can not be processed on the lathe with the core, and when the diameter of the log is small, the rigidity of the log decreases and the quality of the veneer is poor, at this point, if the remaining wood core discarded or processed into wood core board, will result in a great waste of raw materials, thus increasing the cost of veneer production. Therefore, the manufacturers generally adopt no-card log veneer to re-cut the remaining wood core, so that the raw materials have been fully utilized.

Working principle of non-clamping rotary cutting machine for round wood

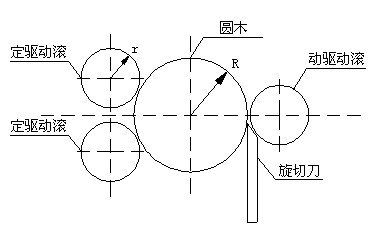

The schematic diagram of the working principle of the card-free rotary cutting machine is shown in the following diagram. The log rotates under the driving of two rotating center fixed rollers and one rotating center moving roller, and the rotary cutting force is produced. The center support of the drive roller and the rotary cutter are fixed and moved together so that the rotary cutter cuts the sheet out of the log and the veneer thickness is controlled by the clearance between the drive roller and the rotary cutter and the speed of the Rotary Cutter's movement.

The clearance between rolling and rotary cutter is relatively fixed, and is adjusted by the cutter clearance adjusting device, which depends on the thickness of the rotary cutting plate. Therefore, the moving speed of the rotary cutter also indirectly determines the thickness of veneer.

As can be seen from Fig. 1, since the rotational speed of the driving roller is constant, that is, the rotational velocity of the log is constant, and the angular velocity of the log changes with the diameter of the log, that is, the time needed for the log to rotate once also changes, so the moving speed of the rotary cutter is a variable value and a nonlinear relation. The control of traditional centreless veneer is mainly based on the method of 2T series electromagnetic speed governor, the speed of the motor is changed by adjusting the input voltage of the controller by manually adjusting the torque or by adjusting the cam curve. The thickness error of plate produced by this control method is as much as 1mm. Therefore, it is very important to design a system which can control the moving speed of the rotary cutter to control the thickness of the rotary cutting plate.

The basic idea of system design is:

(1) establishing accurate mathematical model;

(2) taking over the original speed control system to achieve more accurate speed control.

Working principle diagram of non-clamping rotary cutting machine

Working principle diagram of non-clamping rotary cutting machine

Gafford control system

Based on the operating principle of the Peeler, Gafford has developed a system which is suitable for various types of peeler in the current market. After practical application in Shanghai, Shandong, Hebei, Guangxi, Jiangxi and other places, solve many mechanical manufacturers for the rotary cutting equipment CNC, automation requirements. The response was generally good.

1.The control system of Gafford veneer veneer adopts GD600 high performance vector frequency converter and veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer veneer vene. The GD600 high performance vector frequency converter adopts TI new generation DSP chip, innovatively uses three-core design, ultra-high speed operation ensures that the complex vector calculation can be fully realized, the torque response is 20ms, and the steady state accuracy is ≤3% . Speed ratio can reach 1:200, steady speed accuracy ± 0.2 c/o, 0.5 Hz can output 180 C/O rated torque.

The application of vector inverter in rotary cutter has the following technical advantages:

2.Gafford Peeler controller product characteristics

The Gafford control system simplifies the mechanical structure of the traditional rotary cutter, eliminates the error caused by the wear of the traditional mechanical equipment, and improves the rotary cutting accuracy. Improve the efficiency of mechanical equipment and wood utilization. After a wide range of applications in various areas, customers generally reflect well, especially in some of the more concentrated areas of rotary cutting machine equipment, has formed a certain degree of visibility. This shows that the control system of Gafford Peeler is humanized in the design of Peeler equipment and good product technology.