The medium and small power general purpose frequency converter is usually voltage-type frequency converter, which adopts ac-dc-ac Operation Mode. When the inverter just on power, because the DC side of the filter capacitor capacity is very large, in just charge the moment of current equivalent to short-circuit, the current will be very large. If there is no charge resistance between the bridge and the capacitor, the equivalent of 380V power supply directly to the ground short circuit, instantaneous bridge rectifier through the infinite current caused the bridge blown up. The charging resistor also consumes a lot of power if the relay or other components are not connected.

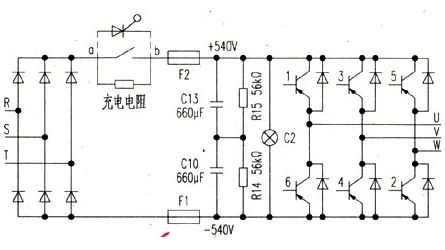

For example, for a 22kW inverter, there is at least 45A current on the PN Terminal (DC bus) . If there is a problem with the“Connect control circuit” part (such as the quality of relays or thyristors, etc.) , the resistance will be damaged by too much heat while the inverter is running. So the charging resistance connected in series in the charging circuit, from the power-on moment limit current charging, to protect the rectifier and other input circuit devices, some books are also called buffer resistance or start resistance. Siemens 6SE701G frequency conversion start circuit as shown in the attached diagram.

After the charge is completed, the resistance is short-circuited by the control circuit through the contacts of the relay or the thyristor to complete the power-on process of the inverter. If the AC input power supply of the inverter is frequently on or off, or if the contact of the bypass contactor is not in good contact or the on-resistance of the thyristor is increased, repeated charging or too long charging time will cause the charging resistance to burn out. Therefore, before replacing the charging resistance, we must find out the reason before putting the inverter into use.

However, some frequency converters have a voltage detection and frequency reduction action during start-up, if the contactor coil lead terminals loose, resulting in poor contact, contactor failed to suck in, the larger the starting current, the larger the voltage drop on the charging resistance. The sharp drop of the DC voltage in the main circuit is detected by the voltage detection circuit, detection circuit will be under-voltage fault“Timely report”, CPU immediately shutdown protection. The resistor can not be burned out in time, and the inverter has been shut down to protect it.

01, how to choose the resistance of charging resistance?

After the 380V AC rectifier, the electrolytic capacitor is charged by the charging resistance, and when it is charged to a certain value (such as DC200V) , the auxiliary power supply starts to supply power to the control board, which makes the Control Board work so that the relay or thyristor is connected, the charging resistor no longer works. At the moment of power-on, the smaller the charge resistance, the greater the current flowing through the bridge rectifier. There are often beginners to call the maintenance of the inverter, replacement of the charging resistance, inverter on, rectifier bridge was blown up immediately, is the charging resistance selection is too small? The answer is no.

In fact, in the boot moment, under normal circumstances, a boot blow up the bridge is not because the choice of charging resistance r is small, but R is too large lead to the explosion of bridge rectifier. Because after the inverter power on, the current through the charging resistance to charge, when the charge enough auxiliary power start (such as 200V) , CPU work, send a signal to the relay or thyristor thyristor let it turn on. At the instant the relay is turned on, the voltage at Relay B is very low (larger than 200V) , and the voltage at point A is AC380V directly rectified to about DC540V, so the voltage difference between A and B is very large. The current is very large at the moment of triggering and conducting, just as there is a small resistance between A and B, and a few hundred volts are added at the moment, so that the current through the bridge is much larger than the rated current of the bridge, so blow up the bridge.

The larger the inverter power, the smaller the charging resistance. Because the greater the power of the inverter, the greater the capacity of the electrolytic capacitor, and the capacity of the capacitor, the longer the time needed to charge. RC decided to charge time, to charge time as short as possible, only the charge resistance r take small. General charging resistance selection: the best value is not more than 300ω, the minimum value is better than 10ω, high-power inverter charging resistance selection small, small-power inverter charging resistance large.

02, energy storage capacity selection

The general selection experience value is ≥60 μf/A. For example, a 15kW inverter with a rated current of 30A needs a capacitance of ≥60μf/a × 30A, i.e. at least 1800μf, so it is common to choose 4 capacitors of 2200μf (two-in-two-series) or 2 capacitors of 4700μf (two-in-two-series) . Of course, also have to consider the brand of selected capacitors, different brands, quality will vary greatly.

Some people repair the inverter only to the damage of the inverter module, often not how long the module again damaged. This can lead to complaints about poor module quality, poor user environment, and so on. In fact, the most important reason is that they did not find out the reason for the inverter module damage, did not completely remove the fault.

The damage of the inverter module, in addition to the long-term overload of the load, poor heat dissipation and lightning shock, the internal causes, capacitor capacity reduction, failure and failure, is the fatal killer of its damage! Its harmfulness can not be ignored. When the capacity is reduced, the light one is characterized by poor ability to carry a load. When the load is heavier, it often causes the DC Circuit undervoltage trip fault. When the capacitor is further damaged, it will form a fatal blow to the inverter module. At this time, the voltage detection circuit can not react in time to report the fault, resulting in damage to the inverter module.

When the capacitor fails or fails (or the capacity becomes smaller) , there is no apparent abnormality when the small power load (big horse and small car) is running, but when the larger power load is connected (full load running) , the situation is different. At this time, the DC Circuit of the inverter has completely (or partially) lost the ability of energy storage filter. DC circuit is the frequency of 300Hz pulsating DC, motor start-up current inhalation, increase the pulsating current components of the pulsating current. This is the resistance to choose a small high-voltage capacitor adverse, resistance to choose a large explosion is one of the reasons. In addition, if the back emf of the motor winding or an output carrier of the inverter happens to fall within the range of the fluctuating DC, the two superimpose each other, and the fluctuating current in the whole system changes sharply, when it falls on a certain frequency point, the distributed inductors and capacitors in the circuit join in from time to time, and various disadvantageous factors join in and interact with each other, so that the dynamic energy in the circuit rises sharply, an instantaneous dangerous resonant overvoltage occurs at this time! The IGBT in the inverter module and the peak voltage absorbing diode in the circuit, their withstand voltage value in normal time has certain or even larger abundance, but at this time under the high voltage impact which is several times higher than the withstand voltage value, there is no defense, but also appears to be very fragile, over-voltage burst and breakdown short circuit is not surprising. Although the inverter has a perfect voltage or current protection detection circuit, but often have to face such instantaneous voltage distortion, appear powerless, or sometimes simply can not make a timely response.

But the bad fault of energy storage capacitor is often hidden, can be said to be soft fault, easy to be ignored. Some capacitance measurement of its capacity seems to be no problem, can also run, but in operation is a big hidden danger. In particular, if the capacitor in the high-power frequency converter is operated for a long time in bad environment, the induced electrode will be charged and discharged by hundreds of Hertz current for many years, and the corrosion and oxidation phenomenon will occur in different degrees, when measured by capacitance meter, the capacity is normal, but when it is connected to the circuit, the internal resistance of charging and discharging increases, which causes the DC circuit voltage to drop, and the frequency converter can not work normally. Re-emphasis: energy storage capacitance capacitance after the extremely easy to appear resonant over-voltage lead to module burst.

Special emphasis

Overhaul more than three years or longer operating life of the inverter, can not ignore the energy storage capacitance check; the inverter module is unknown reasons for damage, it should thoroughly check, replace the DC Circuit of the energy storage capacitance!