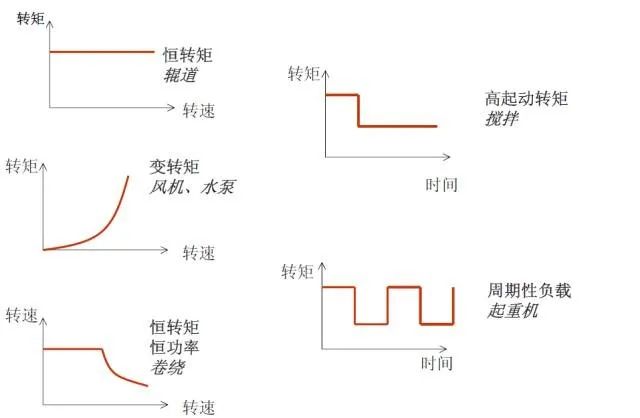

The correct selection of the inverter is very important for the normal operation of the control system. The load characteristics driven by the inverter must be fully understood when selecting the inverter. In practice, people often divide production machinery into three types: constant torque load, constant power load and fan, pump load.

1. Constant torque load

Load torque TL and speed n independent, any speed TL always remain constant or basically constant. For example, conveyor belt, mixer, extruder and other friction type of load and crane, hoist potential energy load are constant torque load. When the inverter drives a constant torque load, the torque at low speed should be large enough and have enough overload capacity. If it is necessary to operate at low speed, the heat dissipation capacity of the standard asynchronous motor should be taken into account to avoid excessive temperature rise of the motor.

2. Constant power load

The torque required for machine tool spindles and coilers and uncoilers in rolling mills, paper mills, and plastic film production lines is generally inversely proportional to the speed of rotation, which is known as constant power load. The constant power property of the load should be in terms of a certain speed range. When the speed is very low, the mechanical strength of the constraints, TL can not be infinite increase, at low speed into constant torque properties. If the constant torque and constant power of the motor, speed range and load constant torque and constant power range, consistent, that is, the so-called“Match” case, the capacity of the motor and inverter capacity are minimal.

3. Fan and pump loads

In a variety of fans, pumps, oil pumps, with the rotation of the impeller, air or liquid in a certain range of speed produced by resistance is roughly proportional to the speed of N to the 2nd power. The torque decreases to the 2nd power of the speed as the speed decreases. The power required for this load is proportional to the power of the speed to the third power. When the required air flow is reduced, the frequency converter can be used to adjust the air flow through speed regulation, which can greatly save electricity. Because the power required at high speed increases too fast with the speed, and speed is proportional to the third power, so generally should not make the fan, pump load overfrequency operation.

Selection principle of frequency conversion

1. The actual motor current value should be taken as the basis for the selection of frequency converter, and the rated power of the motor can only be used as a reference. In addition, due consideration should be given to the output of the inverter with high-order harmonics, will cause the power factor and efficiency of the motor will be bad. As a result, the current of the motor is increased by 10% and the temperature is increased by 20% compared with that of the power grid. So in the choice of motor and inverter, should take into account this situation, appropriate allowance to prevent temperature rise too high, affect the life of the motor.

2. If the frequency converter wants to run long cable, measures should be taken to restrain the effect of long cable on the ground coupling capacitance, to avoid the frequency converter output is not enough, therefore, the frequency converter should be magnified a select or in the output of the inverter output reactor installed.

3. For some special applications, such as high ambient temperature, high switching frequency (especially when used in noise-restricted applications such as building automation) , high altitude, etc. , at this time will cause the reduction of the inverter, the inverter need to enlarge a gear selection.

4. When the inverter is used to control several parallel motors, it is important to consider the length of the inverter-to-motor cable sum in the scope of the inverter. If it exceeds the specified value, to enlarge one or two to select the frequency converter. In this case, the inverter control mode can only be V/F control mode, and the inverter can not protect the motor over-current, overload protection, at this point in each motor to add fuse to achieve protection.

5. For some special applications, such as high ambient temperature, high switching frequency, high altitude, and so on, it will cause the reduction of the inverter, the inverter need to enlarge a gear selection.

6. When using frequency converter to control high-speed motor, because the reactance of high-speed motor is small, high-order harmonics also increase the output current value. Therefore, the choice for high-speed motor frequency converter, should be slightly larger than the general motor frequency converter.

7. When the inverter is used for pole-changing motor, the capacity of the inverter should be selected so that the maximum rated current is below the rated output current of the inverter. In addition, in the operation of pole conversion, should first stop the motor work, otherwise it will cause motor idling, bad will cause damage to the inverter.

8. When the explosion-proof motor is driven, the frequency converter has no explosion-proof structure and should be set outside the dangerous place.

9. When the frequency converter is used to drive the gear deceleration motor, the range of use is restricted by the lubrication mode of the gear rotating part. When lubricating oil is used, there is no limit in the low speed range and the risk of oil running out may occur in the high speed range above the rated speed. Therefore, do not exceed the maximum speed allowed value.

10. When the frequency converter drives the wound rotor asynchronous motor, most of the existing motors are used. Compared with the ordinary squirrel cage motor, the winding impedance of the wound motor is smaller. Therefore, it is easy to occur due to ripple current caused by over-current trip phenomenon, so should choose a slightly larger than the usual capacity of the inverter. The winding motor is usually used in the situation of large flywheel torque GD2, so it should be paid more attention to when setting the acceleration and deceleration time.

11. When the inverter drives the synchronous motor, the output capacity is reduced by 10% ~ 20% compared with the power supply, and the continuous output current of the inverter is larger than the product of the rated current of the synchronous motor and the standard value of the synchronous traction current.

12. For the compressor, vibration, such as torque fluctuations of the load and oil pump, such as peak load, if the motor rated current or power value of the choice of frequency converter, there is a possibility of over-current protection operation due to peak current. Therefore, should understand the power frequency operation, choose more than its maximum current rated output current converter. When the inverter drives the submersible pump motor, because the rated current of the submersible pump motor is larger than the rated current of the general motor, so when the inverter is selected, its rated current is larger than the rated current of the submersible pump motor.

13. When the frequency converter control roots fan, because its starting current is very large, so select the frequency converter must pay attention to whether the capacity of the inverter is large enough.

14. When choosing the frequency converter, we must pay attention to whether its protection level matches the situation on the spot. Otherwise, the site of dust, moisture will affect the long-term operation of the inverter.

15.Single-phase motors are not suitable for inverter-driven applications.

16. When the motor load is very light, even if the motor load current in the inverter rated current, also can not use less than the motor capacity of the inverter. This is because the reactance of the motor varies with the capacity of the motor, even if the load of the motor is the same, the larger the capacity of the motor, the greater the value of the pulsating current, so it is possible to exceed the current tolerance of the inverter.

17. If the inverter power supply is a self-contained power supply, it is best to add into the line reactor.

Source: internet (for study only, intrusion and deletion)